Introduction: Understanding industrial sludge dryers

Industrial sludge is a byproduct of various manufacturing processes that can pose significant challenges for waste management. To address this issue, industrial sludge dryers have emerged as a reliable and efficient solution. These advanced machines effectively remove moisture from sludge, resulting in a drier and more manageable waste product. This article explores the benefits of using an industrial sludge dryer and its impact on waste management in different industries.

1. Improved Waste Volume Reduction

One of the primary advantages of using an industrial sludge dryer is its ability to significantly reduce the volume of waste. By removing moisture from sludge, these dryers can condense the waste material, making it easier to handle and dispose of. This reduction in waste volume not only saves space but also lowers transportation costs, as more waste can be transported in a single trip.

2. Enhanced Energy Efficiency

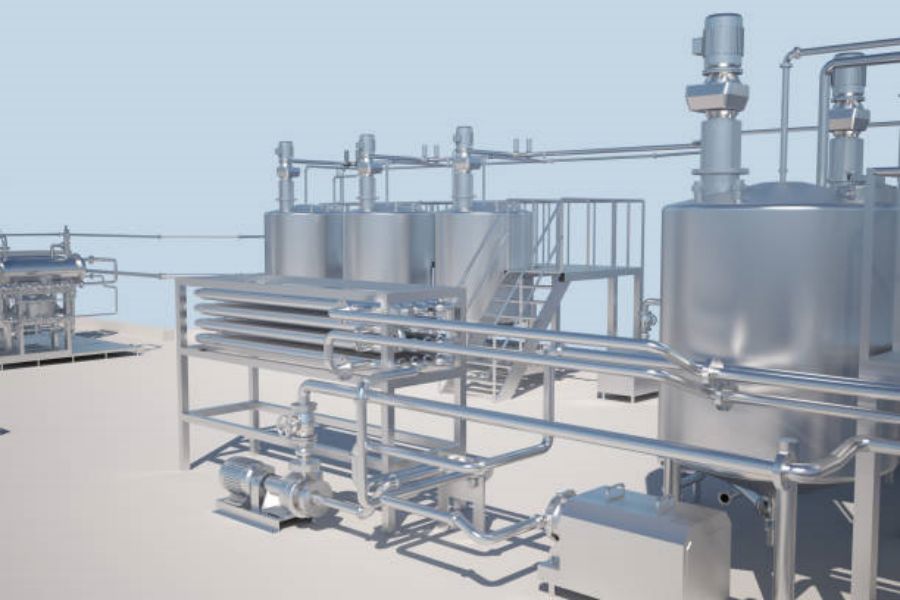

Industrial sludge dryers are designed with energy efficiency in mind. These machines utilize innovative technologies such as heat exchangers and advanced control systems to minimize energy consumption. By efficiently utilizing heat sources, industrial sludge dryers can dry the sludge with minimal energy input, resulting in significant cost savings for industries.

3. Reduced Environmental Impact

Proper waste management is crucial for minimizing the environmental impact of industrial activities. Industrial sludge dryers play a vital role in this regard by facilitating the safe disposal of sludge. By removing the moisture content, sludge becomes more stable, reducing the risk of leaks or spills during transportation and storage. Additionally, by reducing waste volume, industrial sludge dryers contribute to overall waste reduction efforts, promoting a more sustainable approach to waste management.

4. Versatility in Sludge Treatment

Industrial sludge dryers offer versatility in treating various types of sludge. Whether it is wastewater treatment sludge, chemical sludge, or other industrial byproducts, these dryers can effectively handle different compositions and characteristics of sludge. This flexibility makes industrial sludge dryers suitable for a wide range of industries, including chemical manufacturing, food processing, and mining.

5. Enhanced Product Quality

Industrial sludge dryers not only offer waste management benefits but can also improve the quality of certain products. Some sludge byproducts, such as biosolids, can be further processed and transformed into valuable resources. By removing moisture and drying the sludge, industrial sludge dryers create a more stable and manageable material that can be used for various purposes, such as fertilizer production or energy generation.

6. Cost-Effective Solution

Investing in an industrial sludge dryer can be a cost-effective solution for industries dealing with sludge waste. By reducing waste volume, transportation costs are minimized. Furthermore, the enhanced energy efficiency of these dryers leads to significant savings in operational costs. Over time, the cost savings generated by utilizing an industrial sludge dryer can outweigh the initial investment, making it a financially viable option for waste management.

7. Improved Occupational Health and Safety

Industrial sludge can contain harmful substances and pathogens that pose risks to human health and the environment. By properly drying the sludge, industrial sludge dryers can eliminate or greatly reduce these risks. This contributes to improved occupational health and safety for workers involved in the waste management process. Additionally, by reducing the moisture content, the potential for foul odors and microbial growth is minimized, creating a more pleasant and hygienic working environment.

8. Compliance with Regulations

Regulatory bodies impose strict guidelines and regulations on industries regarding waste management practices. Utilizing industrial sludge dryers can help businesses meet and exceed these requirements. By effectively drying the sludge, industries can ensure compliance with regulations regarding waste disposal, minimizing the risk of penalties or legal consequences.

9. Longevity and Durability

Industrial sludge dryers are built to withstand the demanding conditions of industrial settings. These machines are constructed using robust materials and designed to operate continuously, ensuring longevity and durability. By investing in a high-quality industrial sludge dryer, industries can rely on a long-lasting solution for their waste management needs.

10. Advancements in Technology

The field of industrial sludge drying continues to evolve, leading to constant advancements in technology. Manufacturers are continually improving the efficiency, performance, and usability of industrial sludge dryers. These advancements result in more effective waste management solutions, providing industries with the opportunity to stay at the forefront of sustainable practices.